How do Vulcan Vents work?

Our baffle-free design allows air to flow freely.

To repeatedly block embers, we use a stainless steel mesh. It’s simple, strong, and effective. Next, is our intumescent honeycomb. This allows air to flow freely and in the presence of high heat, will swell the vent shut, creating an active fire wall when you need it most!

Blocking fire threat before it's too late.

Our vents are designed to protect against flying embers even before the Vulcan Matrix closure. Embers often attack a home miles before the fire even comes near, spreading flames faster and wreaking more havoc. Our vents are equipped with a screen to catch embers before they enter the home, smolder and ignite, an imperative feature to help keep a home standing during wildfire.

Home safety

starts with venting.

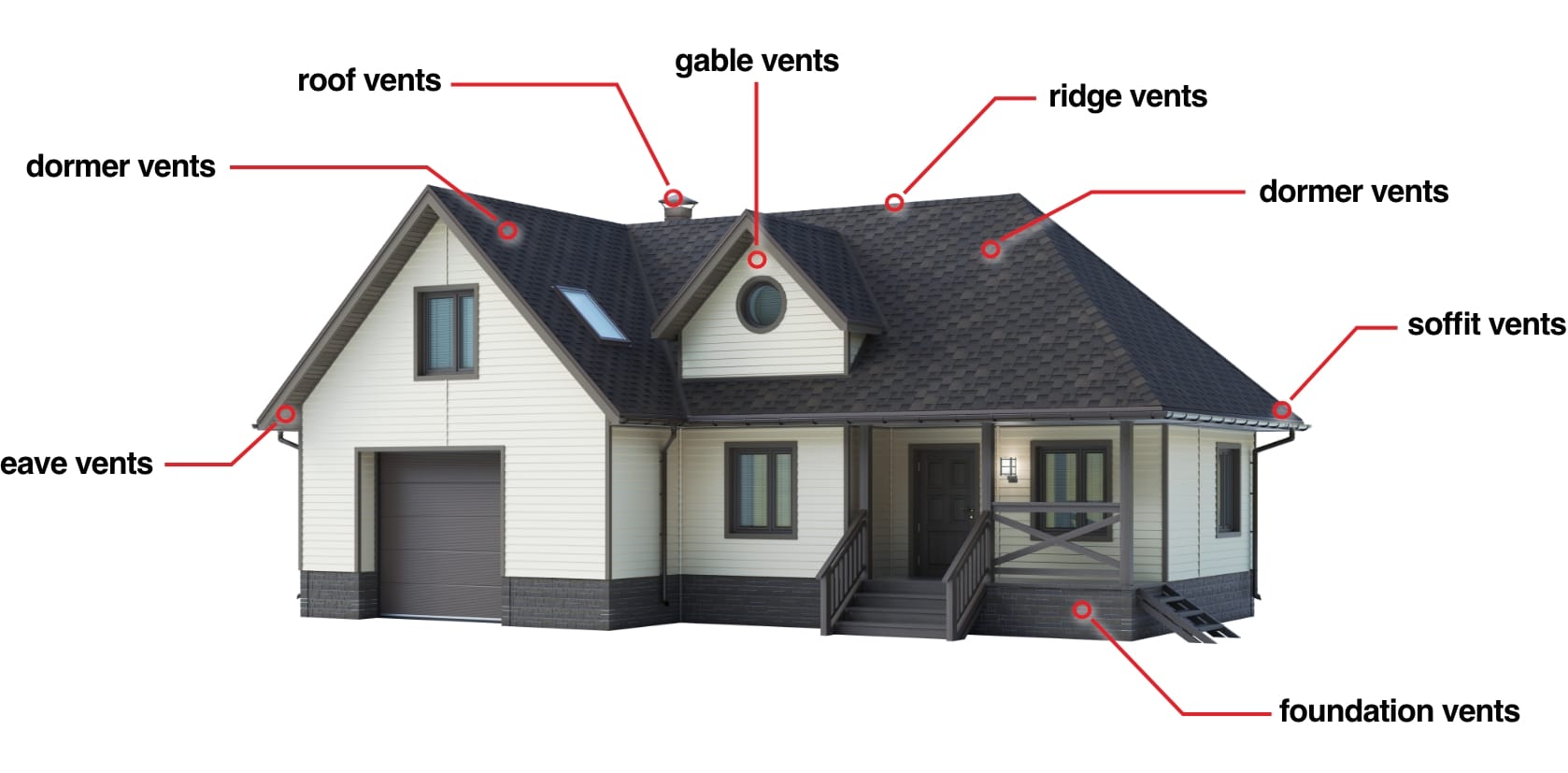

Vulcan Vents will stop floating embers from entering the home through the:

Tested

and Proven

Our vents officially passed the American Society for Testing and Materials (ASTM) E 2886, which is a test to evaluate the ability of exterior vents that mount vertically or horizontally, to resist the entry of embers and flame penetration through the vent.

Fire-rated vents are

more than necessary, they’re required.

Under Chapter 7A California building code, new homes in the WUI must be equipped with ventilation made with building material that are ready for exterior wildfire exposure. We are 1-hour rated, flame and ember rated, and compliant in Canada’s newly evolving building code!

VULCAN VS THE COMPETITION

Corbett and Grace Lunsford from ‘Home Diagnosis’ TV series managed to get their hands on the 3 leading fire and ember-resistant vents. This is a comparative, airflow performance analysis of each type of technology currently available.

- Option #1: Vulcan honeycomb matrix (intumescent coating)

- Option #2: metal baffles (intumescent strips)

- Option #3: silica fibers

Restricting your home’s ventilation can lead to mold and increased energy costs. With more airflow per vent, you’ll likely need less of them for your home to breathe properly. This will also reduce labor costs if you’re retro-fitting or facing an inspection by the fire marshal. Vulcan Vents, just makes more sense!

Source: Home Performance YouTube channel

Fire Resistant Homes: Testing Vulcan, Silica, and Baffled Intumescent Vents

What makes us different?

Highest airflow! Our matrix allows for exceptional ‘net free vent area’ (NFVA). More airflow means fewer vents needed for your home to breathe properly.

Smaller mesh size to catch even the smallest embers.

Intumescent formula coating that expands and closes COMPLETELY to outside fire threat.

Behind the scenes of a Vulcan Vent.

The core of our fire and ember-resistant vents are manufactured out of corrosion-resistant, high-grade aluminum honeycomb, complete with an intumescent coating made by Firefree Coatings. The hexagonal intumescent coating is designed to quickly swell up and close off when exposed to high heat. The expanded material acts as an insulator to heat, fire.

Vulcan Vents vs. Standard Vents

Vulcan Vents

Fine mesh screen stops ember entrance while allowing for adequate airflow when fire isn’t near. When exposed to flames, the fire-resistant coating on the inner honeycomb matrix will expand and effectively fill the space between the cells, creating an effective barrier. Ember resistant and fire rated, Vulcan Vents are advanced wildfire defense.

Standard Vents

Always open with one layer of protection at most from only the largest of airborne objects. Standard vents are not effective at preventing ember entry into attics and basements, potentially causing encompassing fire. As a result, standard vents are not recommended or permitted in buildings near the Wildland-Urban Interface (WUI).

It's all about response time

This graph shows the time it takes for the intumescent honeycomb matrix in Vulcan Vents to expand, stopping fire from getting into crawl spaces and attic spaces and potentially igniting combustible materials.

The blue line shows the results of a standard vent and the bottom three lines show the results of three different Vulcan Vents.

The intumescent coating begins to expand when exposed to radiant heat starting at 450F, then fully expands at 500F at rate of 70 to 1, effectively sealing off the vent and protecting it from the intrusion of flames.